Our goal is customer satisfaction. For this reason, our products are based on cutting-edge solutions designed with attention to technical specifications, quality, reliability and, last but not least, operator safety. As a result, the practicality and ease of use of our products, even the most sophisticated ones, is often a customer satisfaction point. The “friendly” approach to the use of machines, even the most complex ones, renders the machine extraordinarily “familiar” to the operator in a very short time, thanks to the efficiency of the software and a careful study of the man-machine interface.

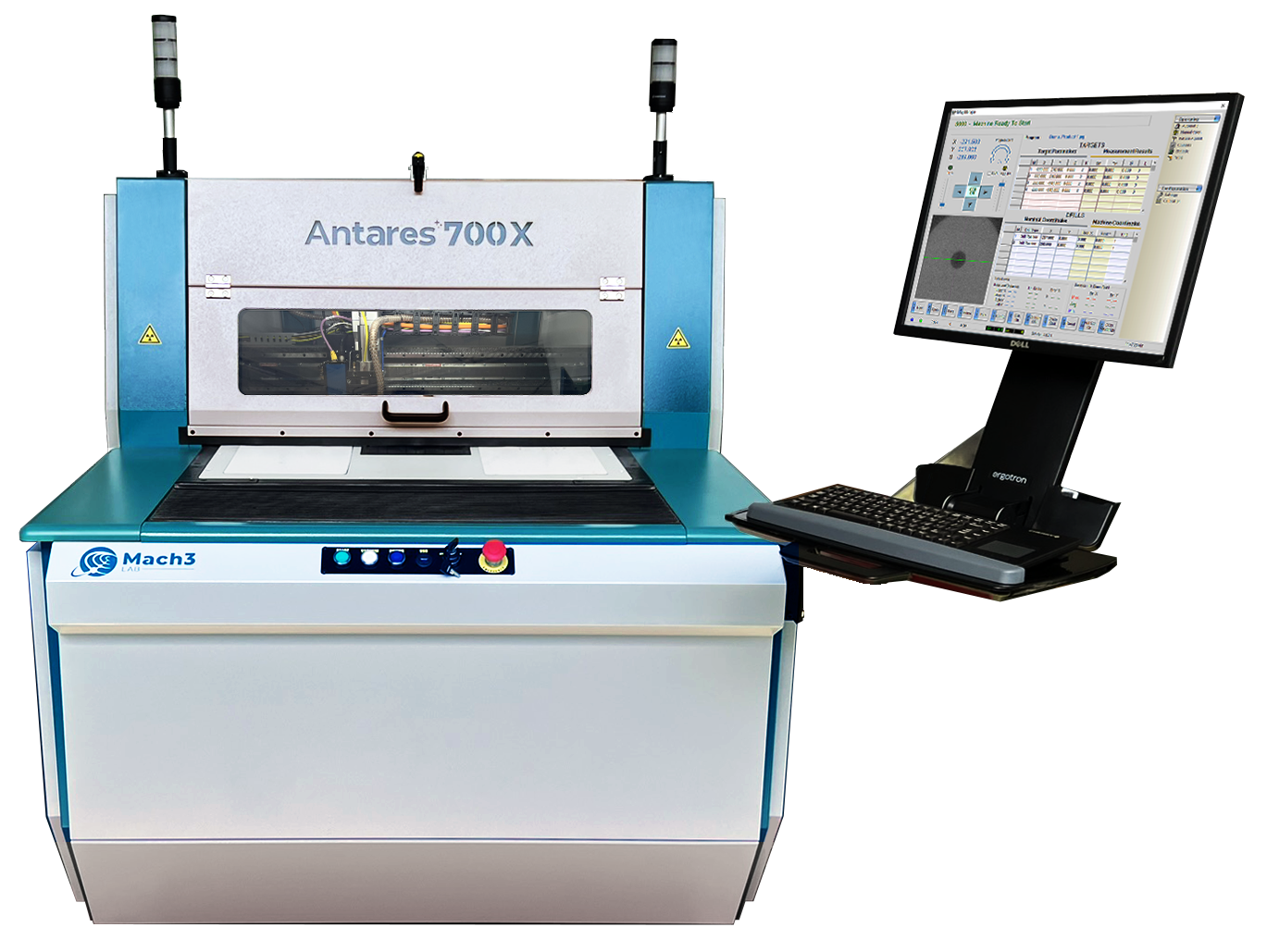

The Antares 700 X is a CNC machine equipped with an X-ray vision system for the optimized execution of the tooling holes and any other mechanical reference on multilayer panels and inner layers.

The Antares 700 XA is designed to make reference holes on multilayer panels such as the Antares 700 X, but with the addition of automation for the loading / unloading of the panels, which allows the machine to operate independently after starting the working cycle.

The Galaxy 700 XB is a processing line that, in addition to performing the optimized drilling of the reference holes after processing the panel with X-rays, eliminates the “flash” from the panel edges and rounds the corners, allowing good and safe handling for subsequent processes.

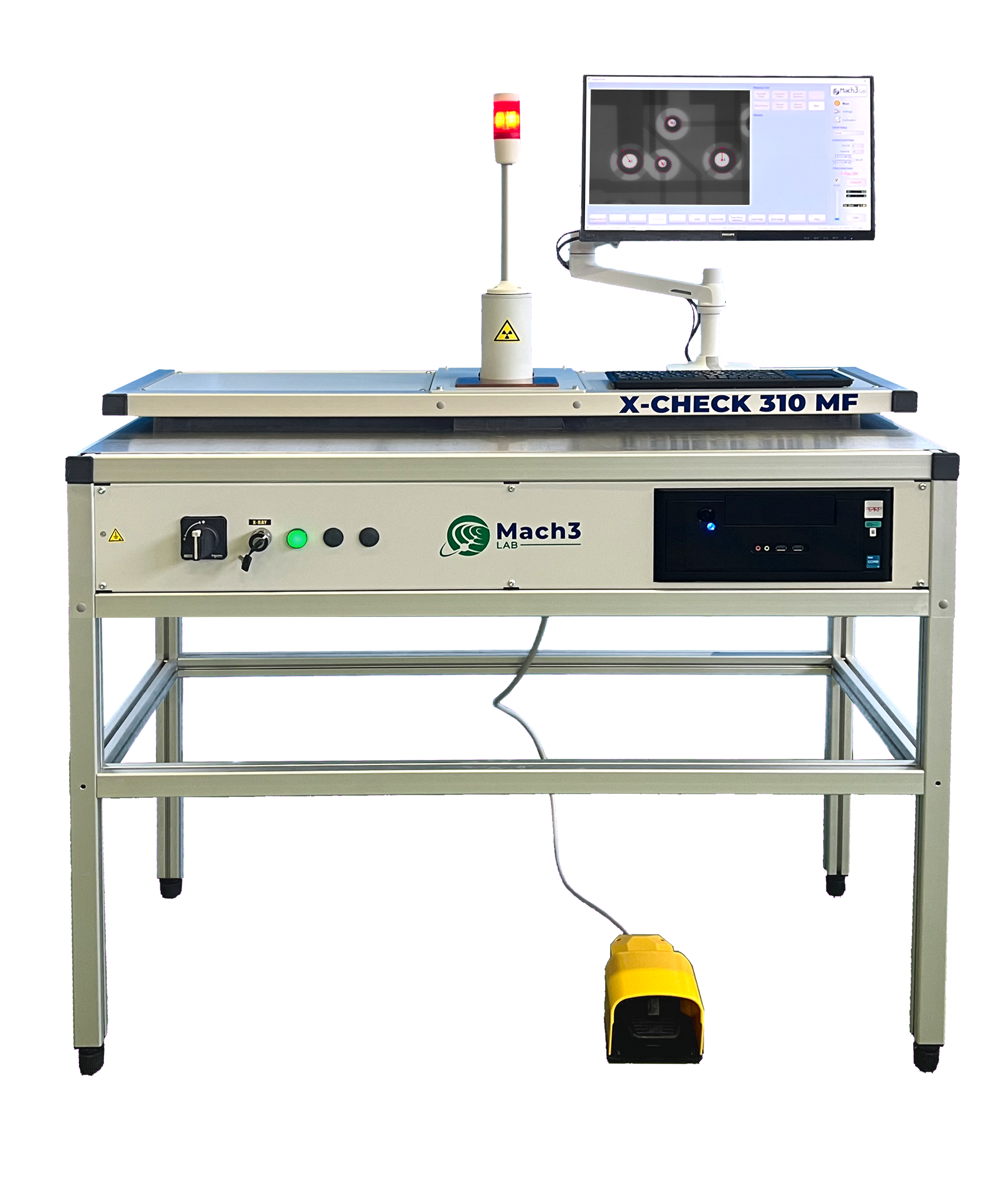

The X-Check 310 MF is an inspection bench that enables the quality-control of the CNC drilling process of multi-layer panels to be performed by measuring the centering error between hole and pad.

Sede legale: Via Dal Pozzo 14 – 13900 Biella – Sede operativa: Strada Provinciale 593 – 13040 Alice Castello (VC) – PI: 02317620025 – REA: 186169 – Tel: +39 0161 909127 – Fax: +39 0161 1890277 – Email: info@mach3lab.com

Privacy Policy – Cookie Policy – Realizzazione sito web e Web Marketing: Netycom Srl